Hydro Motion

For 15 years our boats have been successfully sailing on the power of the sun. This means 15 years of sustainable innovation and inspiring the maritime sector for 15 years. In 2020 the team took the big next step towards a sustainable maritime industry by exploring uncharted waters and starting a new project; the Hydro Motion project. The team built world’s first flying hydrogen boat!

This year, we will take the next step in bridging the gap between “technology of the future” and the current norm by implementing the newest technologies.

In just one year we will design, build and race an innovative next-level foiling hydrogen-powered boat. To put our boat to the test, we participate in the Open Sea Class of the Monaco Energy Boat Challenge. Here, we are going to excel in speed, manoeuvrability and endurance to become world champions and initiate action

We, together with our whole team, are very excited about the project! If you feel the same, follow us on our social media channels to keep up with our progress during the year @hydromotionteam

Hydrogen

Why do we use hydrogen to achieve our goal? As scientists have been warning for years, the supply of oil and gas will inevitably run dry, and the exploitation of these energy sources will lead to irreversible climate change. We need to use different approaches if we want to move towards a zero-emission future.

There are several options to generate green electricity. These include wind and solar generated energy. To come full circle it is essential that we do not only look at the supply side of the chain, but also pay attention to the way we store this energy. Right now, the industry tends towards the usage of chemical cells when it comes to storing energy and powering electric transport. However, this is only part of the solution to reducing carbon emissions in the transport industry, because different applications require different solutions and the demand of lithium is growing faster than the supply can satisfy.

This is why we focus on an alternative way of storing green energy. The most prominent contender in our opinion is hydrogen. Using hydrogen as an energy carrier has the benefit that it doesn’t produce greenhouse gas emissions when used to generate electricity. On top of that hydrogen -when converted by fuel cells- has an energy storage density approximately 235 times larger compared to industry standard lithium ion battery cells. This is a huge advantage when it comes to powering a vessel.

When we show what our boat can do, we prove the viability of hydrogen. By working together with the maritime industry itself we can inspire change. We are all part of a problem, which means we can all be part of the solution. Only by working together we can sail to a sustainable future!

Last year's design

The first seaworthy monohull

This year was the first year we designed a hull for hydrogen. This led us to design a monohull, this means that the hull of the boat exists out of one piece. With this we also designed the first seaworthy monohull of the foundation. The two seaworthy boats before us used a trimaran. This monohull allows us to use all the space as efficiently as possible and be more manoeuvrable, which is important for our race.

On top of our boat we have two caps, but these are not just for show. If we have a hydrogen leak, the hydrogen will float upwards. Our two tanks are right below the caps, so the caps make sure the hydrogen has a place to leave the boat. This ensures more safety for our pilots in the boat.

Both the hull and the caps are made of carbon fibre, a light and strong material. To make sure our hull can withstand the rough conditions of the Mediterranean sea, we analysed exactly how many carbon layers we needed.

16 kg of hydrogen

The hydrogen we use to propel our boat is stored in the tank, located under our caps. Our hydrogen is stored in a gaseous state at 350 bar. To make this comprehensible, 350 bar is the pressure you would feel when two elephants would be standing on the palm of your hand. And even under this immense pressure, our tank is still 2,3 meters long and has a diameter of 50 centimetre. Now in our boat, we will be carrying 2 tanks of hydrogen, this is 16 kilograms which is double the amount of last year’s boat!

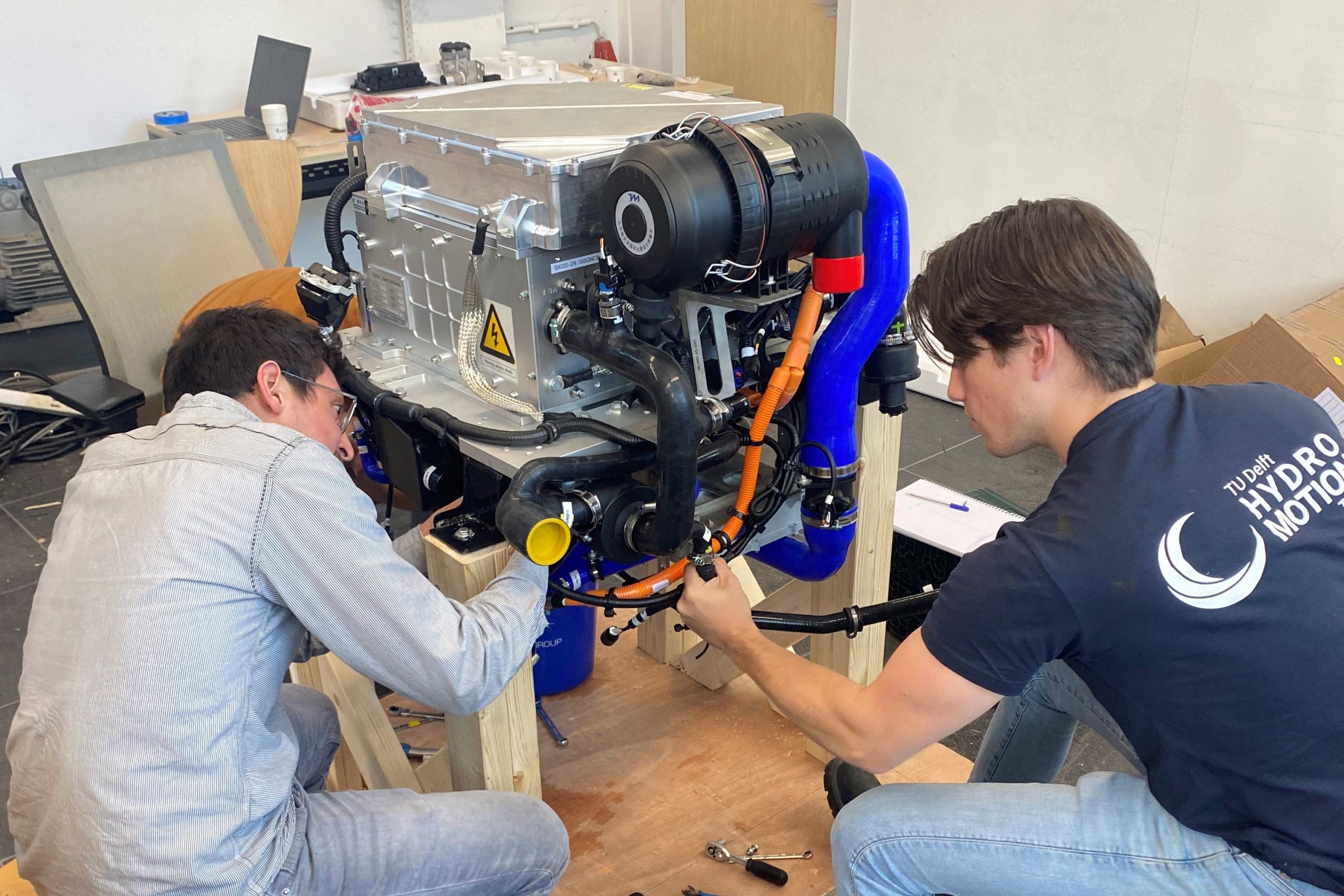

From the tank the hydrogen goes to the fuel cell. A fuel cell is a device that uses the chemical energy in hydrogen and transforms this into electricity. Our fuel cell uses hydrogen and oxygen to form water and generate electricity. We use this electricity to power the our boat.

The beating heart of our boat

The beating heart of our boat is our fuel cell, but to understand how our fuel cell actually works, we need to take a closer look at hydrogen itself. Hydrogen is an atom, an element. A hydrogen molecule consists of two atoms. You see two protons and two electrons.

Hydrogen goes from the tank to the fuel cell and passes through the proton exchange membrane. This is like a filter that only allows protons to pass through, but it blocks the electrons. That’s why, when a hydrogen molecule reaches the proton exchange membrane, it splits up into two protons and two electrons. The protons then pass through the filter to join an oxygen atom on the other side to form water. Because of the membrane the electrons have to travel through an external circuit, producing a direct current. However, we are not just letting it go through any ordinary external circuit, we are powering our boat with this!

A FLYING hydrogen-powered boat

Besides building a hydrogen-powered boat in just one year, we also make it fly! When a boat picks-up more speed, the drag with the water increases leading to more energy usage. By making our boat fly we avoid using those big amounts of energy, making our boat much more efficient. When sailing the foils create an upwards force, known as lift. When sailing faster, the foils create more lift. The foils and the struts lift the boat out of the water when we reach our take off speed of 25 km/h

The waves we face when we fly on the ocean influence the balance of our boat. That’s why we actively control our foils with a height control system. We have three sensors that constantly measure the height and orientation of our boat. That means that, when our starboard side drops ever so slightly, our sensors measure this and tell the starboard foil to adjust its angle of attack: generating more lift and re-balancing our boat. This way we can stably fly for extensive periods of time.

Propulsion

Just like many other boats we use a propellor to move forward. However with our struts and wings underneath the boat the mechanism connecting the propellor to our electro motor is quite complex. The propellor has to be at the end of the strut so it will always be submerged even when we are flying. The electro motor however cannot fit in this strut. This make the usage of a driveline necessary. The driveline translates the rotating of the electro motor down the strut into the propellor, making it spin. This is how we can keep moving forward even when we are flying.

We started this year in August, full of enthusiasm, but with little to no clue about what to expect of this year. We quickly got to know each other better and learned how to work together as a team. Only by working together as a team we can reach our ambitious goal; winning the Open Sea Class of the Monaco Energy Boat Challenge.

To reach this goal we started with the design of our boat. We dedicated five full months to our design and eventually we showed you the final design of our boat; The first seaworthy monohull of our foundation! Then it was time for the production phase.

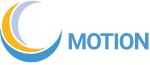

Hull production

The first thing you need when you want to withstand the Mediterranean waves is a seaworthy hull.

That is why our team spent over 10 weeks at one of our partners to produce our hull, caps, bulkheads, hatches and the deck. This was a challenging phase for our team; not only did some of our teammates work there, they also lived there meaning we had to miss them for 10 weeks.

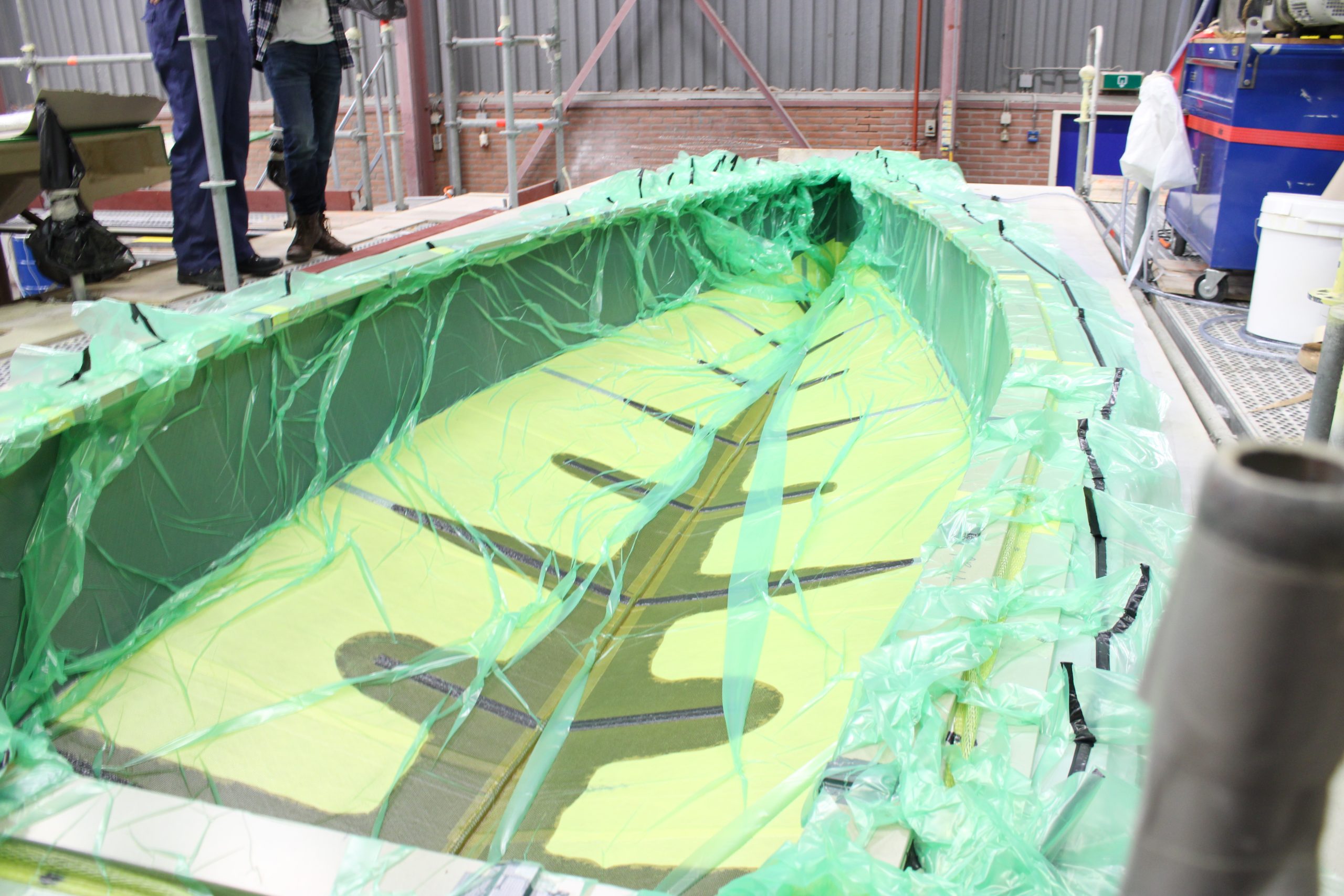

Wing production

Later in the year, we also had to miss our Vehicle Dynamics department for the production of our hydrofoils. In just 4 weeks they produced two full sets of hydrofoils that will make our boat fly!

Dreamhall

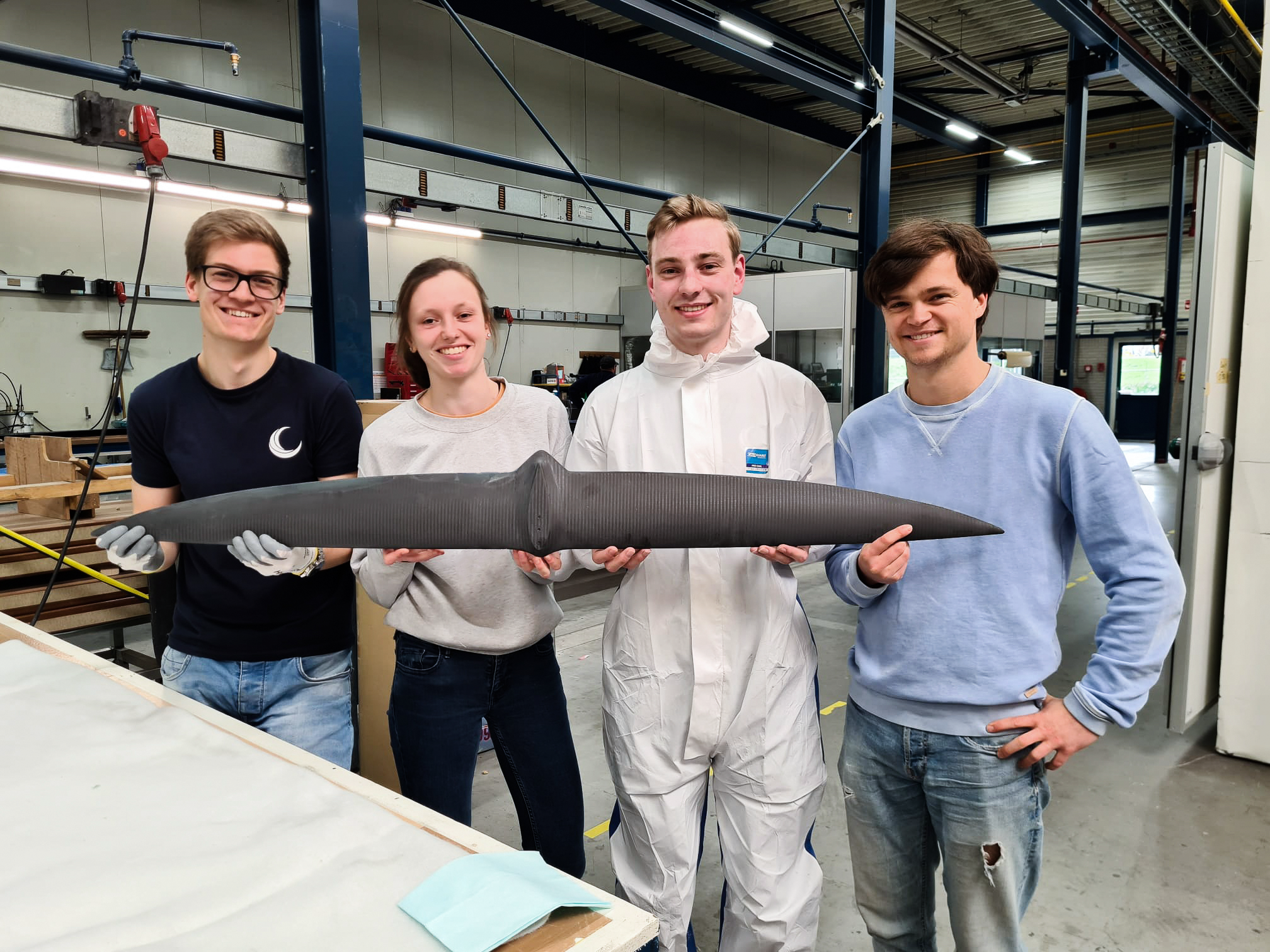

During this time, we of course didn’t sit still ain the Dream Hall!

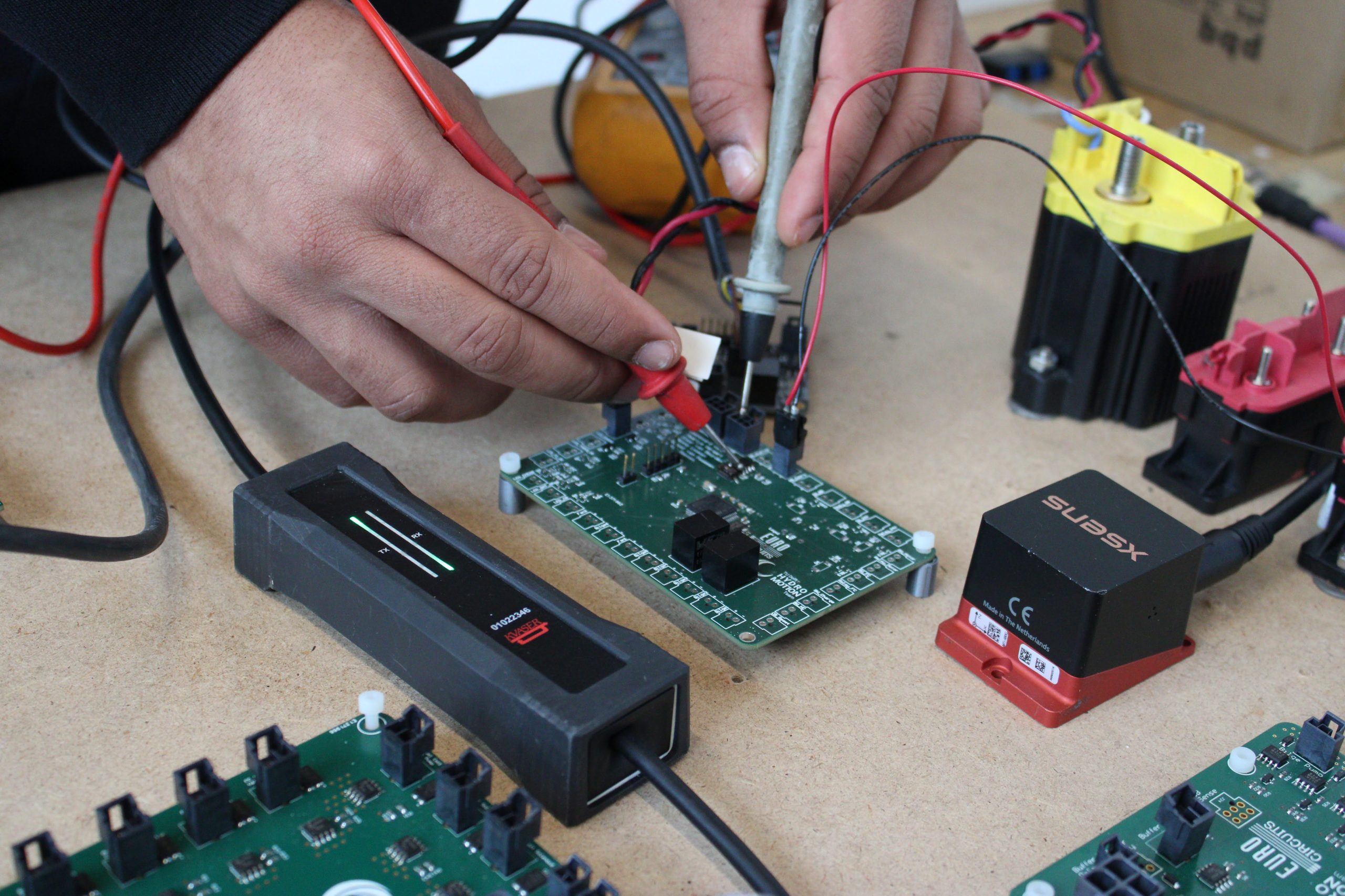

We started the production of all of our other mechanical and electrical subsystems. We soldered, drilled, milled, developed software and called with experts to reach our goal: winning the Open Sea Class with a flying hydrogen-powered boat!

However, this is easier said than done. We had to push ourselves, work hard and make long days. To give you an idea; one of our Vehicle Dynamics engineers, Michiel, spent more than 300 hours behind the machines. Kyon, our software engineer, wrote over 9.000 lines of code to control the movement and behaviour of the boat. And our Powertrain department drove more than 12 hours to pick up our second tank.

Assembly

After all the individual parts and subsytems were produced it was time to assemble our boat. At that moment all the seperate parts designed by our different team members had to come together and be integrated into one working boat. Everything had to fit and communicate with eachother to make a flying hydrogen-powered boat.

We are so proud of what we have achieved as a team. We all learned so many new things, overcame challenges together and helped each other through difficult moments. But we wouldn’t be were we are now without the support of our partners. So, we want to thank our partners for helping us. Only by working together and combining our strengths we can accomplish our mission: accelerating the energy transition in the maritime industry.

The boat reveal

O

Opening

Our event was kicked-off by Suzet Giltay, the moderator of the day.

The day was a very important day for the team; we revealed our boat for the first time to the world. It was amazing to see that so many people were gathered and that we could physically meet each other to celebrate this moment.

We kicked off with a presentation given by our Team Manager Sophie van ‘t Hoff. Then Raoul Boucke, member of the House of Representatives, was interviewed after which the boat was revealed and christened!

Team Manager

“Today, our Christening, marks the official end to our production phase! The past months were filled with hard work. We soldered, drilled, milled, laid carbon, called with partners and developed software to reach our goal: winning the Open Sea Class with a flying hydrogen-powered boat!

After all this effort, it is so rewarding to be standing here today and to be able to show you our boat. We all learned so many new things, overcame challenges together and helped each other through difficult moments.

Only by working together and combining our strengths we can accomplish our mission: accelerating the implementation of sustainable energy technologies.”

Production Video

This video is a summary of what our past months looked like. We are so excited we made our design reality!

Interview

Raoul Boucke is someone who has been fighting for the climate for the past couple of years and who has been actively advocating Climate and Energy policy throughout his career. Before joining the House of Representatives, he worked in Brussels for thirteen years on behalf of the Netherlands to negotiate European climate policy. This included a European CO2 emissions trading system, a sustainable European transport network, and tackling sea-level rise. Both him and the team are driven by one goal: to empower people to join the journey to a more sustainable future. “I am very excited about the work of the TU Delft Hydro Motion Team! We all should be proud of the work of these young innovators and engineers. They are the people who push the sustainable innovation forwards,” said Raoul Boucke

During the interview we talked about this experiences with climate change. Raoul Boucke grew up in Suriname where he saw what beautiful nature we can lose if we don’t take action. This activated him to pursue a career in sustainability. Within the government they are making money available for alternative sustainable fuels. Raoul Boucke believes that hydrogen can play a big roll in the energy transition. “We need a more sustainable transportation urgently, and hydrogen plays an important role in making the transition reality,” said Boucke. Raoul advised us to be proud of what we achieved and that we should share it with the world.

Reveal

Then, for the first time, we proudly revealed our flying hydrogen-powered boat.

It was such an amazing moment for us to share with everybody. This would not have been possible without the support of our partners, all of them closely involved with the design and production of our boat. But also, our friends and family that have supported us in other ways to make this all possible.

Christening

Then, it was time to christen our boat, blessing it with a successful voyage in Monaco.

It was an amazing day to share with everyone there and the team is looking forward to the next phase, the testing phase. The testing phase will prepare us for Monaco, where we will put our boat to the test and demonstrate the potential of hydrogen!

Aftermovie

___

Aftermovie