14-06-2024

Testing Update

Newsletter June

Over the past weeks, we have been putting our boat to the test. Having secured its yearly spot in Drimmelen, only a few meter sail away from the Amer, our boat has been undergoing rounds of tests, troubleshooting and in-water fixes. Upon much fixing and tuning, we sailed for the first time. Initially, powered only by our battery, and finally, powered by hydrogen. Reaching these milestones brought us closer to our goal of crossing the North Sea and set the stage for our latest achievement: our first flight!

TESTING UPDATE

As for any engineering project, our testing phase has presented us with some challenges, and made us aware of both the capabilities and the limitations of our systems. The process of encountering issues, brainstorming, and implementing solutions has been quite rewarding and brought together our engineers from different departments.

Here is a snapshot of what we have achieved so far:

First Successful Sail

After fixing issues with the steering system by adding a shunt, we conducted our first sailing test with Anna. We navigated out of the harbour and onto the Amer, performing several manoeuvres. Despite initial challenges with the steering radius at low speeds, we managed successful 180-degree turns and completed our wet electric test requirements.

Hydrogen Fuel Cell Tests

We officially conducted our first hydrogen wet test, producing water on the water. Initial tests revealed some safety and technical challenges, but we made significant progress in fine-tuning our fuel cell protocols and addressing sensor errors.

First Flight

After a morning of testing the roll and pitch capabilities of our foils and heightcontrol mechanism without taking flight, with a little bit of troubleshooting afterwards, we got ready to foil for the first time, in the afternoon. Around 17:00, our boat successfully lifted 60cm out of the water and soared above it at almost 50 km/h, demonstrating the potential of our design. Minimal tuning allowed for stable foiling, turning and landing. After several trials and a test of our emergency landing feature (which proved to out-do the pilots themselves, smoothtly and swiftly getting our hull back in the water), we concluded a day of successful foiling.

Celebrating this achievement, we enjoyed a BBQ, marking the occasion of our first successful foiling test with our hydrogen-powered foiling boat. The day's efforts and results have set a promising foundation for our upcoming North Sea crossing!

BON VOYAGE

A major focus point of our Operations department is the organisation of our very last event of the year: the Bon Voyage. This event will happen on the 24th June, at Campus@Sea, in Scheveningen. During the Bon Voyage, we shall sail our boat in front of family, friends, partners and press, thereby demonstrating the capabilities of our boat and the strength of hydrogen. We will celebrate all our achievements, which will culminate in a hydrogen-powered foiling boat that is ready to cross the North Sea.

Ultimately, we will bid it a Bon Voyage!

CROSSING UPDATE

While our boat is being tested in the water, a crew back in Delft works on the preparations for our North Sea crossing. Here are some highlights from the process:

Logistics

Transporting the boat and our equipment back to the Netherlands involves numerous procedures and considerations. Our current plan is to use the Eurotunnel for most equipment, while the boat will be transported via ferry. We are also looking into how to get the whole team to-and-fro England. We have secured accommodation at all the stops in our journey, covering the entire weather window for our North Sea crossing.

Legal

We are continuously in contact with all legal entities to ensure that our crossing will follow all rules and regulations. Both the Dutch and British Coast Guards have given tentative approval for our crossing, and we are in close contact with the Port of London Authority for the possibility to sail on the Thames.

Safety

We have created a detailed emergency map, indicating which harbours to head to in case of emergencies.

UPCOMING STEPS

Starting Monday, we will be moving our testing headquarters from Drimmelen to the Scheveningen Harbour! Here, our pilots will be sailing on real life North Sea conditions, in order to prepare them for the long crossing ahead. These final two weeks, we will be collecting data and making the last adjustments, ensuring optimal performance during our crossing, including the fine tuning of our height control to adapt to the North Sea waves.

Newsletter

The next newsletter will be out in a month! Do you know someone who is not yet receiving this newsletter but would like to? Send an email to exposure@hydromotionteam.nl or click on the link below. Via the link, you can enter an email address and will be asked to confirm via Mailchimp's email. Feel free to send any comments or questions to exposure@hydromotionteam.nl

16-05-2024

2024 BOAT REVEALED

Newsletter May

On Thursday May 2nd we revealed our newest hydrogen-powered foiling boat to the world! We were joined by many partners, family, and friends at the NDSM wharf in Amsterdam. Here we enjoyed a presentation consisting of a hydrogen lecture by Ad van Wijk, a panel discussion with our Operations Manager Ellis Huistra, John Geel from the KNRM and Marco Rehbein from team Out of the Blue about sea travel, and a summary of our production phase from our Chief Hull & Body Carolina. We ended the presentation by ceremoniously “christening” our boat, a traditional maritime tradition to wish us a safe and inspiring journey!

If you were unable to join us during the boat reveal, or would like to have a small reminder of the event, you can watch our aftermovie below or on our youtube channel!

PROGRESS UPDATE

The boat reveal marks a very important next phase in our project: the start of Wet Testing. The next coming weeks we will diligently test all aspects of our boat in the water at our testing location in Drimmelen. Here we will fine tune all our systems in order to ensure optimal performance, and attempt to find any faults in our boat as quickly as possible so we can fix them on time. This phase is crucial to our project, as we get to see all of our hard work over the last few months pay off. Make sure to follow our socials and keep an eye on our website to stay up to date on our testing progress!

However, before we got to this phase we first completed two other phases: production and assembly!

PRODUCTION AND ASSEMBLY PHASE RECAP

Production was the phase where we were able to see all individual parts come to life, whilst assembly was the moment we were able to see all parts come together to form a cohesive whole. After assembly we were finally able to say that we had built a hydrogen-powered boat!

HULL & BODY

Although the Hull & Body department has returned from Contest Yachts having finished our beautiful hull, they have most definitely not been sitting still since. Part of the department has been busy installing the hydrogen system of our boat, as well as other structural aspects such as the hatches and windshield. This culminated in our boat returning shortly to Medemblik to glue on the deck, and cure the hull in its entirety. Furthermore our hull, deck, and all the hatches have been wrapped. Our hull is now seaworthy and ready to start testing!

EMBEDDED SYSTEMS

Embedded Systems had been hard at work assembling all cables, sensors, and electronic systems in the boat. The cables are being inserted through waterproof cable passes with the help of Roxtec, ensuring that the different compartments of the boat remain waterproof. Furthermore, they have been hard at work on the height control mechanism, fitting the sensor at the front of the boat and calibrating the motor controller.

VEHICLE DYNAMICS

Vehicle Dynamics spent 4 weeks at an external location in order to do foil production at Qconcepts Design and Engineering. Here they received guidance in producing our foils to perfection. We are very happy to have them back, and we’re very excited to see the foils come to life! The rest of the department that stayed in Delft was hard at work assembling our cooling system, essential for the components in our boat. We have both a closed and open loop cooling system, requiring a complicated array of tubes, fittings and pumps. Furthermore, there was a lot of work left to do on the motor mount, steering mechanism, and the other systems.

OPERATIONS

The Operations department has been hard at work organising multiple events and visits. We are very happy to have been able to welcome some new partners for a look around our work place. This year we were also very excited to organise the Dream Career Day on March 19th together with Project MARCH, Brunel Solar Team and Forze Hydrogen Racing. A month later we were very excited to welcome 3 of our partners at our Dream Hall Partner Day! Here we learned about our partners through cases whilst they were able to see the Dream Hall where we have been working full time since August. Furthermore we were busy at work preparing for the Boat Reveal, and are now working towards our final events and the crossing!

For a video recap of our production and assembly phase, check out the video below!

CROSSING UPDATE

Since the return of the Hull & Body department from Medemblik, another department has started taking shape; the Crossing Committee. This committee is responsible for organising all legal, safety, logistics and strategic aspects that are crucial for helping us cross the North Sea at the beginning of July. The Crossing Committee is in close contact with many of our partners that help on a safety and strategic level, such as Sima Charters who will provide us with a support vessel during the crossing, and the KNRM who advise us on safety concerns. The coming months this group of team members will continue working tirelessly to prepare for our challenge.

Newsletter

The next newsletter will be out in a month! Do you know someone who is not yet receiving this newsletter but would like to? Send an email to exposure@hydromotionteam.nl or click on the link below. Via the link, you can enter an email address and will be asked to confirm via Mailchimp's email. Feel free to send any comments or questions to exposure@hydromotionteam.nl

18-02-2024

Production

Newsletter Februari

Production Phase

Hydro Motion Team '24

The last few weeks our team has been hard at work with the production of our foiling hydrogen-powered boat! Let’s delve into the latest updates and developments.

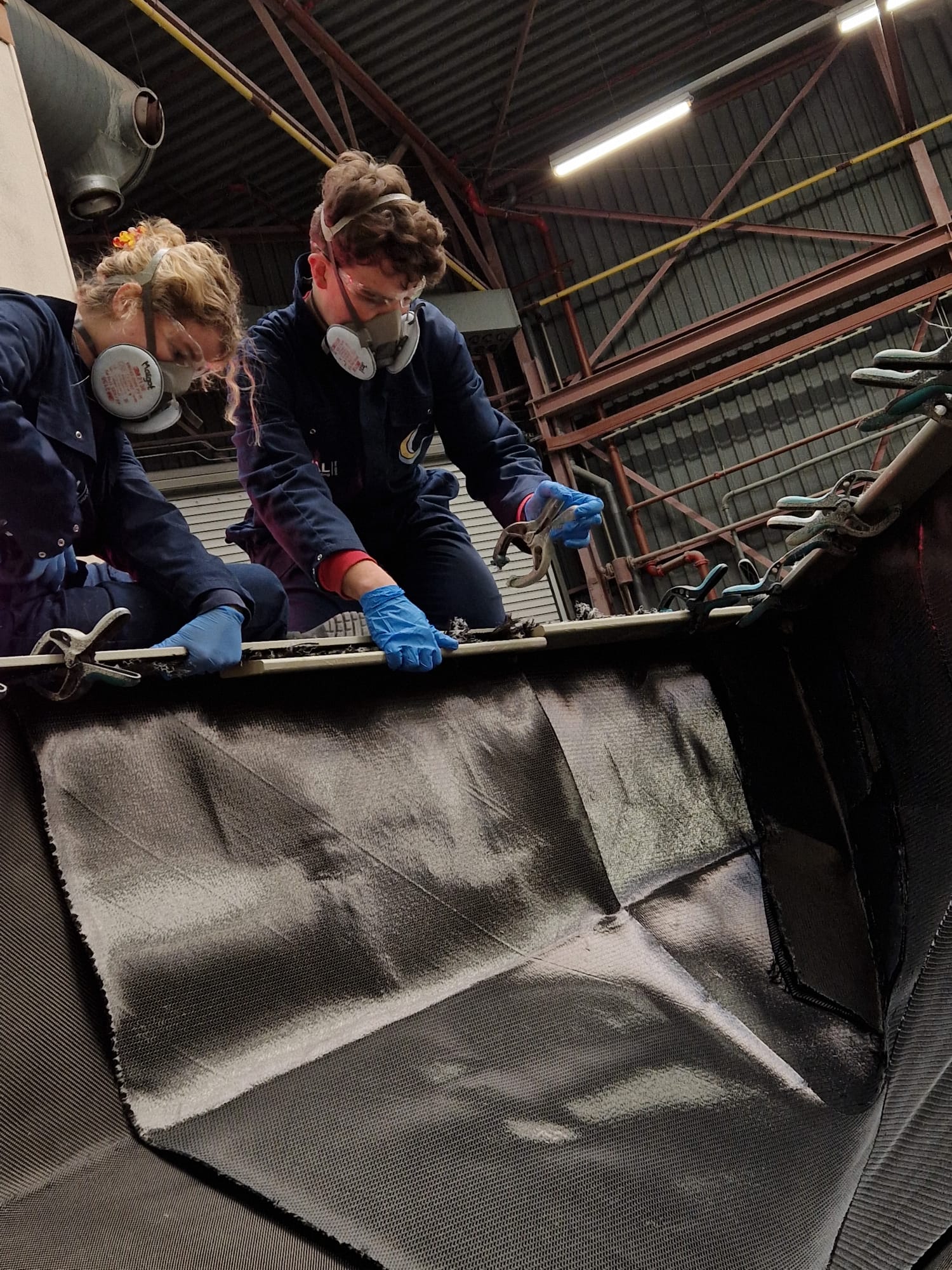

PRODUCTION UPDATE

Our hull & body department continues to work hard at production of our hull at the location of one of our partners: Contest Yachts. They have finished the bulk heads and deck plates, and have just successfully infused the hull with resin! This was a very exciting (and scary) step, as weeks of hard work of preparing the mold and laying the carbon have led to this moment. We are very happy and proud that this step was successful, and that this milestone was reached!

After this they will be working to finish the hull, and start with the lamination of stiffeners, bulkheads, sleeves, and the deck.

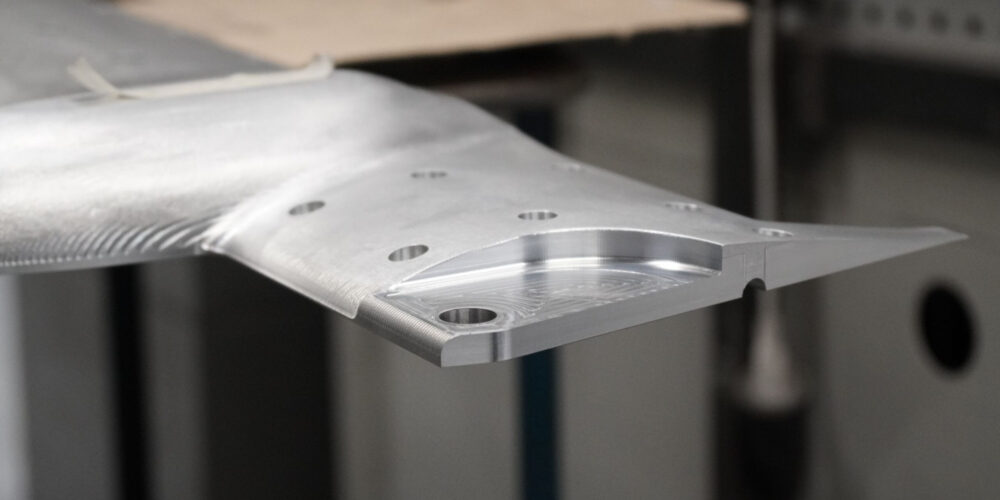

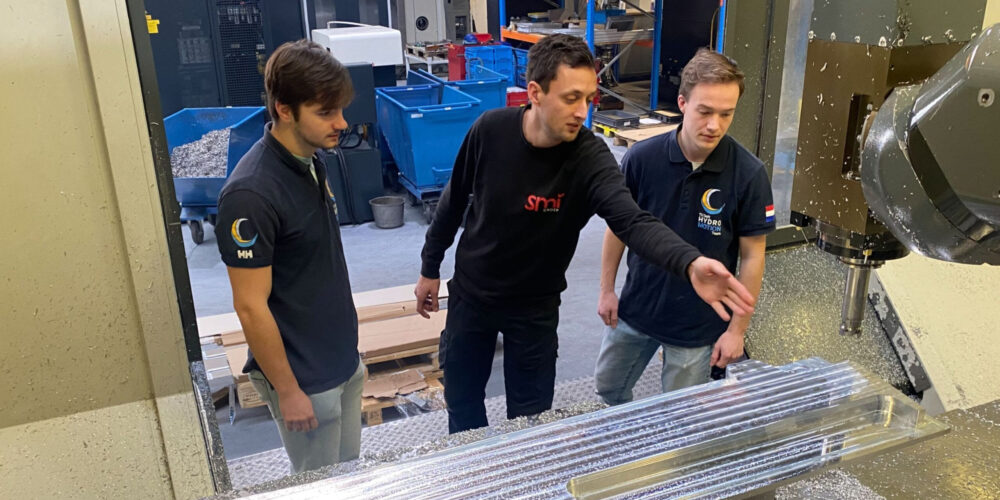

Vehicle Dynamics has finished the production of our sleeves, and have received the final struts from our partners! With the help of Jatec we were able to CNC our front struts, whilst our other partner, SMI Verspaningen, helped us produce our rear strut. It is very exciting watching so many parts of our boat come to life.

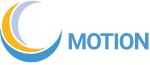

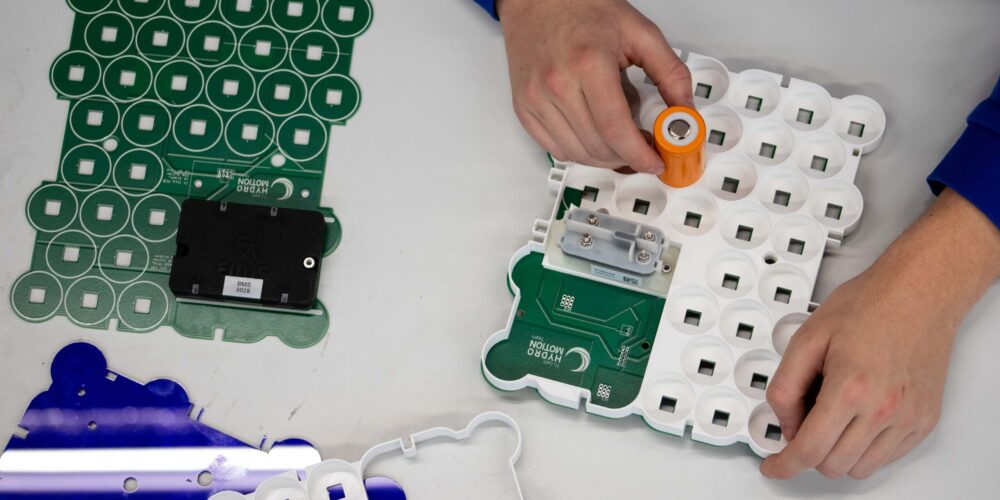

Meanwhile, Embedded Systems has recently started the assembly of our electronic boxes at Royal Van Der Leun. They are busy with the production of the steering system, the high voltage system, and the software for the boat.

Finally, the Operations department is busy organising events, running recruitment, and maintaining contact with our partners, whilst management is preparing for the upcoming phase of the project: Assembly!

Newsletter

Do you know someone who is not yet receiving this newsletter but would like to? Send an email to exposure@hydromotionteam.nl or click on the link below. Via the link, you can enter an email address and will be asked to confirm via Mailchimp's email. Feel free to send any comments or questions to exposure@hydromotionteam.nl

15-01-2024

We started Production!

Newsletter January

Production Phase

HMT24

First of all, happy new year!

This will be the year that we, the TU Delft Hydro Motion Team of 2024, cross the rough waters of the north sea between the Netherlands and the United Kingdom and we are extremely excited about the challenge.

However, we have a bit of a journey ahead of us before we hit those waves. Rounding up the detailed design phase marked a milestone for our team as we could finally share our newest design with the world. Now, as we transition into the production phase, everything that was designed gets to come to life! Let’s delve into the latest updates and developments of each department.

HULL & BODY

Our five Hull and Body engineers have already been producing for about three weeks at Contest Yachts in Medemblik and plan to be there for about eight more. Just like in the past couple of years we are using carbon vacuum infusion to produce our hull. What is different however, is that due to the size of our boat design, we're using a split-mould from Nedcam instead of a direct mould. Aligning the two sides carefully is therefore crucial since we require the mould to be vacuum-tight. Managing this task becomes quite a challenge with the mould dimensions at 8.5 metres by 3.2 metres. In recent weeks, their focus has been on preparing the mould, consisting of activities such as waxing, fitting inserts, and creating plates for the deck and bulkheads. These preparations set the stage for the upcoming weeks. Looking ahead, our Hull and Body department will continue with the production of the hull and deck, laying down the foundation for the project. |

EMBEDDED SYSTEMS

In recent weeks, the Embedded Systems department has been busy designing the electrical systems that enable the boat to sail and fly. They have determined the placement of cables, components, and electrical boxes.

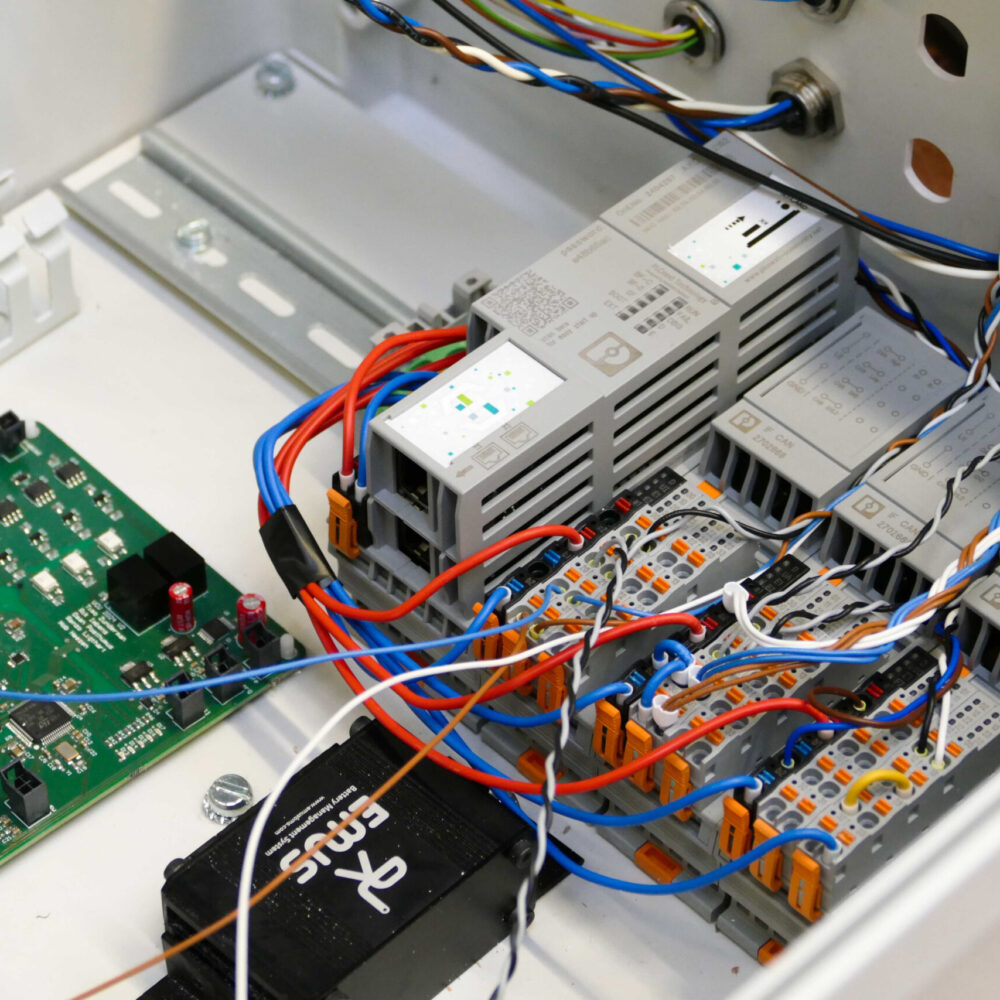

Subsequently, they have been actively involved in designing PCBs and writing software to integrate all components and are also engaged in constructing a new high-voltage battery. They will start assembling and testing the battery at IONBASE in Muiden coming week. While continuing writing software and building the complete electrical system for when the boat arrives from production in Medemblik.

VEHICLE DYNAMICS

The Vehicle Dynamics departments’ production phase doesn’t align perfectly with the other departments, but they have definitely not been sitting still. Faced with the need to work extensively with previously unfamiliar machines, such as CNC and milling machines, the department has dedicated their time to following various courses and becoming experts at them. At the same time, they have been creating all the designs for the parts, getting ready for production.

This will allow them to start producing a lot of parts in the coming weeks. Parts they produce are for example the steering and foil actuation as well as the sleeves, which connect the struts with the hull. Then in March they will start the production of another extremely important thing, the foils. The department is going to produce these at Qconcepts this year.

OPERATIONS

With the Design Presentation just behind us the Operations department is already shifting its focus to the next big event, the reveal of the boat! This will take place in spring and the department will work on preparing this event in the coming weeks. Next to the big event there are also several partner related events that they are focussing on.

Besides event planning the department is busy with designing the wrap of the boat. This will be done in collaboration with the team through brainstorm sessions and opportunities to voice their opinions.

Newsletter

For the coming weeks we will be working on finishing our detailed design, preparing for production and working hard on all preparations for the Design Presentation. Do you know someone who is not yet receiving this newsletter but would like to? Send an email to exposure@hydromotionteam.nl or click on the link below. Via the link, you can enter an email address and will be asked to confirm via Mailchimp's email. Feel free to send any comments or questions to exposure@hydromotionteam.nl

24-12-2023

Design Revealed!

Let's sail into 2024 together!

Boat Design

Hydro Motion Team

2024

Last Wednesday, 20th December, we finally presented the design of our brand-new foiling hydrogen-powered boat. After countless hours, long days and hard work, we are incredibly proud to share the design with you. In case you missed the live presentation or simply wish to relive the moment, you can watch the entire presentation on our YouTube channel:

Happy Holidays!

Now, as we dive into the new year, we're rolling up our sleeves for the production phase. We are all very excited to start seeing our boat come to live and truly hope you will be following along.

For now, we want to wish you a great and festive end of 2023. We are excited to get back to work again in 2024 and want to thank you for your support in making our dream, of crossing the North Sea on a fully hydrogen powered boat, come to life!

From all of us at the TU Delft Hydro Motion Team, Happy Holidays and we wish you a happy and healthy 2024!

Newsletter

For the coming weeks we will be working on finishing our detailed design, preparing for production and working hard on all preparations for the Design Presentation. Do you know someone who is not yet receiving this newsletter but would like to? Send an email to exposure@hydromotionteam.nl or click on the link below. Via the link, you can enter an email address and will be asked to confirm via Mailchimp's email. Feel free to send any comments or questions to exposure@hydromotionteam.nl

01-12-2023

Newsletter

1st of December, 2023

The New Hydro Motion Team

Last August, we had the honour of taking over the Hydro Motion Project, thereby becoming the 2024 Hydro Motion Team. We are a brand new team of 23 multidisciplinary students who are dedicating a full year towards designing, producing, testing and sailing a flying hydrogen-powered boat!

These last few months we have been very busy starting up with our team, setting our goals for this year, and designing our boat! We are currently nearing the end of our design phase, with production starting off in december. This is all to reach our scope:

“In one year, we will design, build and test a hydrogen-powered boat and sail between the Netherlands and the United Kingdom”

We started this year by revealing ourselves and our goals in the “Team & Scope Reveal” video, which you can watch here:

Design Process

Our design process involves three different stages: Top Level Concept, Sub Level Concept, and Detailed Design. We're currently in the final Detailed Design phase, meaning that the finishing touches are being placed on the design of our boat. However, before reaching this phase, we first completed the top and sub level concept phases.

During the top level concept we determined the internal and external constraints of our design. We asked ourselves questions such as “In what conditions do we need to be able to foil?”, “What are the necessary measurements of our boat?” and “What will our propulsion system look like?”. Answering these questions, and many more, lead us to making the biggest decisions regarding the design of our boat. Following this phase we went more in depth, which also involved dividing our team’s engineers into three different departments:

Hull & Body - Responsible for the design and production of the hull, and internal architecture of the boat. Additionally, they design the hydrogen systems, ensure structural integrity in the boat, and manage the weight distribution of all systems.

Vehicle Dynamics - Ensures proper function of all moving parts in the boat. This department is responsible for the struts and foils, as well as the steering and cooling systems. The Vehicle Dynamics department sees to it that our boat will be able to fly above the water!

Embedded Systems - Takes charge in all electronic and technical systems. These engineers are involved in connecting all sensors and systems, and making sure they work together seamlessly. Beyond internal coordination of all systems, they also ensure effective communication between the boat, safety vessels, and the mainland.

Besides the engineering departments there is also the Operations Department; they are responsible for marketing and all communication to the outside world, and Management; who facilitate the team to be able to reach their goals. For a more in depth look into our different departments you can find the department reveals on our instagram page!

Newsletter

For the coming weeks we will be working on finishing our detailed design, preparing for production and working hard on all preparations for the Design Presentation. Do you know someone who is not yet receiving this newsletter but would like to? Send an email to exposure@hydromotionteam.nl or click on the link below. Via the link, you can enter an email address and will be asked to confirm via Mailchimp's email. Feel free to send any comments or questions to exposure@hydromotionteam.nl

08-07-2023

Newsletter

8th of July

Speed Challenge

Today was our last racing day.We started the day full of confidence having scored second place in the Manoeuvrability Challenge and first place in the Endurance Challenge. The upcoming Speed Challenge was very important to us because we could finally show the potential of hydrogen to the world. We knew that we had fierce competition as our competitors with their battery-powered boats can achieve high speeds. This made it a challenging and exciting day. We started the day with a good feeling, because we were very happy with the results of the previous days and we were confident about this race.

Yesterday we experienced for the first time how rough the Open Sea can be. From the start of the race today, we noticed the waves hitting the boat and flooding the deck. It was very difficult to handle these rough conditions. In the beginning we were close to our competitors and we immediately tried to foil above the waves. Due to the big waves a lot of water entered the boat, causing technical difficulties. We investigated the problem and tried to fix it on sea. However, the waves were too high to safely perform maintenance and the decision was made to tow Aurora back to the harbour. In the harbour the whole team rushed together to fix the boat and so we could sail again.

After consulting with the race organisation, we decided to stay in the harbour to guarantee the safety of our boat and the pilots. Our strategy crew was confident that we would stay ahead of our competitors thanks to the amazing results of the previous days. We became world champions in the Monaco Energy Boat Challenge! We are extremely proud of what we have accomplished here in Monaco. We sailed efficiently on hydrogen and we foiled stably on the Mediterranean waves. We showed that by working together in a high-performing team you can build a fully functioning boat in just one year, because only together we can turn the tide.

Back to Delft

After our final race, the Speed Challenge, our journey in the Monaco Energy Boat Challenge 2023 has come to an end.

In the evening we attended the prize ceremony as World Champions! A title we are extremely proud of to take back to Delft. After celebrating our results we’ll pack everything back up. In the coming days we will be driving back to Delft where we’ll tidy up and prepare the handover for next year’s team. After that it is time to relax, reflect and recover from this year of hard work and amazing experiences. We can look back full of pride on the wonderful year we have had.

Newsletter

The last newsletter of the year will be arriving in a week when we have tidied everything up. Do you know someone who is not yet receiving this newsletter but would like to? Send an email to exposure@hydromotionteam.nl or click on the link below. Via the link, you can enter an email address and will be asked to confirm via Mailchimp's email. Feel free to send any comments or questions to exposure@hydromotionteam.nl

07-07-2023

Newsletter

7th of July

Endurance Challenge

Today was our second and most important challenge; the Endurance Challenge. This challenge gave us the opportunity to show the true potential of hydrogen in the maritime industry. For the Endurance Challenge we had four hours to sail as many nautical miles as possible. We sailed the distance in laps, and the boat that completed the most laps wins! For us the trick was to balance the speed with energy consumption. We needed to sail as fast as possible while keeping an eye on the amount of energy we consumed. We had an advantage over the other energy sources because hydrogen has a high energy density. It can therefore carry a lot of energy at a lower weight compared to other fuels. And because we have such an advantage over the other teams we didn't need to sail at full speed so that we have more hydrogen left for the speed challenge.

We were in the lead from the start and really showed why hydrogen is better for endurance than batteries. Unfortunately, about 2;45h into the race the wind started to pick up, creating big waves. We decided to go back to the harbour early to eliminate any risks for our pilots and Aurora. Luckily we already had such a lead that we still finished in first place! The number two did choose to sail the whole four hours but they did not manage to overtake us. This win is a big step towards the World Championship.

Speed Challenge

Tomorrow, we're gearing up for the Speed Challenge! We will sail back and forth to Ventimiglia, an Italian city located 8 nautical miles away. In total we’ll sail 16 nautical miles, equivalent to approximately 26 kilometres. The objective is simple: the fastest boat wins. Thanks to our foils, which reduce drag and enable us to glide over the water, we can achieve speeds of up to 50 km/h compared to the 35 km/h we would be sailing without foils.

Stay tuned

Keep an eye out for the next newsletter to be kept up to date. The next newsletter will be arriving tomorrow after we sailed the Speed Challenge. Do you know someone who is not yet receiving this newsletter but would like to? Send an email to exposure@hydromotionteam.nl or click on the link below. Via the link, you can enter an email address and will be asked to confirm via Mailchimp's email. Feel free to send any comments or questions to exposure@hydromotionteam.nl

See you next time!

06-07-2023

Newsletter

6th of July

Manoeuvrability Challenge

After Aurora arrived on Monday, we had a technical inspection on Tuesday which we passed with flying colours. We had time to test the boat in the harbour for the Manoeuvrability Challenge and we sailed on Open Sea where we almost immediatly foiled!

Today we started the race day with a parade. All the boats participating in the various competition classes could be admired sailing in the harbour. It was an impressive and cheerful parade of solar, hydrogen and battery boats. We are happy to set an example for the maritime industry together. After the parade it was time for our first challenge; the Manoeuvrability Challenge. In this challenge we were tested on our ability to make specific manoeuvres in the harbour. The manoeuvres we had to perform were sailing around a buoy, slalom around buoys and complete a 360 degrees turn backwards around a buoy and end with sailing backwards and docking the boat. We had to complete te course as fast as possible at a speed of max 4 knots. After talking through our strategy for the challenge we could start our first attempt and we finished with a time of 3 minutes and 9 seconds. This resulted in us winning the second place in the Manoeuvrability Challenge, but this is just beginning.

Upcoming Challenges

On the 7th of July we will have our second and most important challenge: the Endurance Challenge. Here we will demonstrate the true potential of hydrogen.

For this challenge we sail for 4 hours straight. The boat completing the most laps wins! The difficulty here is to balance speed with energy consumption. You want to sail as fast as possible, but by doing so you consume more energy and the amount of energy is not infinite. Hydrogen has a huge advantage over other energy sources as it has a high energy density and can therefore provide a lot of energy with less weight.

On the 8th of July we will have the last challenge; the Speed Challenge. For the Speed Challenge we sail to the Italian city of Ventimiglia, which is 16 nautical miles away, a distance of almost 26 kilometres. The fastest boat wins! Our foils make our boat more efficient by reducing the amount of drag by flying over the water. With the same power we can go from 35 km/h to 50 km/h just by foiling.

Stay tuned

Keep an eye out for the next newsletter to be kept up to date. The next newsletter will be arriving tomorrow after we sailed the Endurance Challenge. Do you know someone who is not yet receiving this newsletter but would like to? Send an email to exposure@hydromotionteam.nl or click on the link below. Via the link, you can enter an email address and will be asked to confirm via Mailchimp's email. Feel free to send any comments or questions to exposure@hydromotionteam.nl

See you next time!

26-06-2023

Newsletter

June - A foiling hydrogen-powered boat

Over the past few weeks, we have made our first metres with Aurora. She planes very stable and you can see the effect of the chine beautifully. The spray is immediately directed downwards and generates a lot of lift. To maximise the testing time with Aurora, we work in different shifts. In the past month, we tested the hydrogen systems on full power. After a couple of tries the system was reliable enough to start testing with high speed tests on the water. Aurora sails exceptionally stable, especially when planing. This enabled us to sail safely at a top speed of 42 km/h!

Height control

After those tests, we could start with the height control tests. This is the most exciting but also the most tricky part of testing since every part needs to work together seamlessly. The electrical system must be trustworthy, as well as the foil actuation (and other) software. Mechanically the hull, foil actuation system and struts must withstand all the hydrostatic and -dynamic forces when foiling. Because there are waves we need to adjust the angle of our hydrofoils to keep sailing stably. We have implemented a PID controller which needs to be tuned, we do this ourselves. The PID is like the settings of a computer, we have to alter the settings till the system doesn't over or under react. So by tuning the parameters for height, pitch (rotational motion around the side-to-side axis) and roll (rotational motion around the longitudinal axis) we are creating a stable foiling hydrogen-powered boat.

Friday the 2nd of June marked a significant moment for our team as we embarked on testing our height control system. During our height control testing, we achieved a remarkable milestone as we successfully foiled for the first time! We worked really hard to make this happen and we couldn't be more proud that we achieved part of our goal by building a foiling hydrogen-powered boat. However, this thrilling moment transitioned into a challenging situation when unstable behaviour of the boat led to damage. The boat stayed afloat, allowing us to safely lift it out of the water. Thanks to the pro-active responses of the team members no one got hurt.

Of course, this recent situation was a setback for our entire team. It was terrible to see our boat, which we had worked on so hard over the past year, get damaged. Despite this, we were not going to give up. We, as a team, immediately started planning the repair, and we are confident in our ability to overcome and emerge stronger than ever! The whole team worked very hard to repair everything that was damaged, and in just 10 days we were able to get back to testing again!

During the last two weeks we have worked diligently to restore the functionality of the system after the incident. Some parts broke down, and everything had to be thoroughly tested again to ensure the reliability of the components. The buffer was revised to make it more robust.

We also conducted some tests for the height control and there were significant changes made to the code based on the results. The display of the pilot is also updated to provide more informative feedback and the steering mechanism is improved so the pilot can handle the height control of the boat easier.

Monaco

Besides sailing in Aurora, our trip to Monaco is also getting closer and closer. The hotels for the trip have been booked and we are staying near the port. Over the next two weeks, we will be preparing the finishing touches of the logistics for our trip and our stay in Monaco. That way, we will arrive at the start fully ready for what’s to come.

We are in good spirits for the Monaco Energy Boat Challenge and are looking forward to competing in the Open Sea Class. The first challenge we have to complete in Monaco is the manoeuvrability challenge. For this part we’ll need to complete a certain route as fast as possible with a maximum speed of 3 knots which is about 5,5 km/h. Because there is a maximum speed it is all about the pilot’s and the boat’s manoeuvring ability.

The second challenge we’ll face is the endurance challenge. This challenge allows us to really show the potential of hydrogen and the difference between hydrogen and battery powered boats. All boats will get four hours to cover as much distance as possible. Because batteries are so much heavier than hydrogen, we can take more energy with us and therefore sail further.

The last challenge is the speed challenge, this will be intriguing because batteries can release more energy in a short time compared to hydrogen. This means that we’ll need to foil to improve our chance of winning. Monaco is approaching very fast so at the moment we are on the end sprint and working hard to get the best out of the boat.

Newsletter

For the coming weeks we will be testing the boat in the water and we’ll prepare for the race. The next newsletter will be out in two weeks when we’re in Monaco! Do you know someone who is not yet receiving this newsletter but would like to? Send an email to exposure@hydromotionteam.nl or click on the link below. Via the link, you can enter an email address and will be asked to confirm via Mailchimp's email. Feel free to send any comments or questions to exposure@hydromotionteam.nl

See you next time!

Newsletter

January

Taking the next step

First of all I would like to wish you a Happy New Year on behalf of the TU Delft Hydro Motion Team. Before the holidays, we had an amazing Design Presentation where we could finally share our design with all of you. Let’s look back briefly on this wonderful night!

Over the last 17 years we have built amazing boats that sail on sustainable energy sources, inspiring the maritime industry to move to a more sustainable future. But now it is time to take action; with our design, it is time to turn the tide.

This year we want to win the Monaco Open Sea Class in July 2023 with our foiling hydrogen-powered boat. With this in mind, we researched the possibilities to reach our goal and we started designing our boat. After making hard choices and working long days we finished our detailed design phase.

The hydrofoils are an important part of our boat because they enable the boat to “fly” above the water, which is called foiling. When the boat is foiling the drag becomes significantly less and therefore we can sail faster with less fuel. With this mechanism we can win the World Championship in Monaco.

Foiling is important to win the Monaco Open Sea Class 2023, because it allows us to reach a similar speed as our competitors who sail on batteries. In order to foil, the boat needs to reach 25 km/h. At this speed, the hydrofoils create enough lift to raise the 1400 kg boat out of the water. Because the competition takes place on the open sea, the boat has to withstand waves that can make the boat unstable. At the same time, the boat also needs to be lightweight to foil. In order to get this done we made some improvements compared to last year.

Hull and Body

The Hull & Body Department has focused on a lighter and more efficient hull shape. The boat has become more efficient by adding the chine, the horizontal ledge, where the bottom transitions to the side. In addition, the bow has been rounded and the boat is optimised for our hydrogen system. This year we’ll have a dead man’s switch, which means we’ll only need two pilots compared to three pilots last year. Because of this, the position of the fuel cell has moved forward and the tanks are placed more to the middle instead of the side of the boat. This allows the boat to be more compact and thus lighter. Ultimately, the weight of the boat affects its foiling characteristics.

Embedded Systems

This year the focus of the Embedded Systems department is to make the electrical system robust and reliable, while keeping it as simple as possible. The department will reuse many components of last year’s boat, such as the fuel cell and the motor controller. However, they will also produce and use many new and innovative components. The department will receive a new, stronger and more efficient motor from Emrax. Besides this, they will make use of a new step-down converter from Brightloop to create the lower voltages needed for all auxiliary systems. The auxiliary systems consist of all systems required in addition to the power system, such as the bilge pumps and display.

We are also designing and producing a new buffer this year, which will have a lower mass and will be safer to use. Lastly, the system architecture and height control system will have a completely new design. The cable tree is redesigned, new Printed Circuit Boards are designed, and the height control system will be designed in such a way that it will be more reliable and responsive.

Vehicle Dynamics

The Vehicle Dynamics department has been really busy designing parts in CATIA for the last 2 months. CATIA is a 3D digital modelling program developed by Dassault Systems. They not only designed the cooling, steering and foil actuation system, but also the driveline, struts and foils. It was a very busy period in which they used a lot of knowledge of our partners and alumni. The Vehicle Dynamics department has been working hard on optimising the height control system. This is the system that will enable us to foil in a stable manner. It consists of the actuation system, sensors and control system. The latter is the custom programmed PID controller, which is a way of optimising the flight characteristics.

Operations department

The Operations department was busy with organising the Design Presentation before the holidays. Not only the content of the presentation needed to be written, but also the music, light, and countdown had to be prepared for the presentation. The department worked hard on organising the drinks and questions afterwards. Besides organising the presentation, Operations actively worked on our social media and press releases, and External Relations worked on staying in touch with our partners.

Did you miss the Design Presentation?

You can see our design on our website: https://hydromotionteam.nl/project-3/

The after movie is out now as well!: https://www.youtube.com/watch?v=uE6uny99XO8

Do you want to see the whole presentation?

Recorded livestream: https://www.youtube.com/watch?v=0ka29Rcal9s

Production

Now that the design phase is finished, we have started the production phase. Everything we designed will be produced, which is really exciting! From now on we will slowly see our design come to life.

Hull and Body

The Hull and Body department has already started production of the hull at Contest Yachts in Medemblik. During production, the department puts a lot of focus on their personal health and safety. They are wearing proper personal protective equipment which is needed when working with carbon fibre. They are building the hull in a direct mould of about 8 by 3 metres and, despite this size, they were able to set the mould down with a precision of 1 mm. This shows that the department works meticulously to minimise the weight of the boat. The Hull and Body department is now 3.5 weeks into production and they plan to build the hull within 7 weeks.

Embedded Systems

During the coming weeks the Embedded Systems department will be designing, producing and testing all components of the electrical system. There are a lot of different systems, which all have to be controlled by software. The department will design and solder PCB’s, which are debugged and tested thoroughly. After that they will put most of the components in watertight boxes from Phoenix Mecano so that the electronics can be put safely in the boat. We will then connect everything together with cables from Phoenix Contact and Van der Leun so that the data and power can be transferred between the systems. After that everything will be dry tested thoroughly, so that we are sure that everything is working correctly when we test the boat in the water.

Vehicle Dynamics

The coming weeks the Vehicle Dynamics department will produce a lot of parts. Those include parts for the steering and foil actuation, but most importantly: the custom designed foils. The department is going to produce these at Rondal in February. Next to that, the struts are being produced in the Dreamhall with the help of Salim, the CNC programmer of the Dreamhall. Furthermore, the sleeves, which connect the struts with the hull, are also produced in-house. In week 6 we will install those in the boat, which will then still be at Contest in Medemblik, together with the tube assembly (connection between the rear strut and hull).

Operations department

The coming weeks, Operations will be busy with designing the wrap of the boat. Designing the wrap will be done in collaboration with the team through brainstorming sessions and by giving the team the opportunity to voice their opinion about the different concepts of the wrap.

Even though we’ve just had our Design Presentation, Operations is already working on the next event. The Christening of the boat will take place in spring and the department will work on preparing this event in the coming weeks as well.

Newsletter

For the coming weeks we will be working hard on the production of the different parts we need for the boat. The next newsletter will be out in a month! Do you want to receive this newsletter in your inbox? Send an email to exposure@hydromotionteam.nl or click on the link below. Via the link, you can enter an email address and will be asked to confirm via Mailchimp’s email. Feel free to send any comments or questions to exposure@hydromotionteam.nl

See you next month!

Newsletter

December

A new year, a new team, a new boat

Each year there is a whole new team that is eagerly waiting to take over the project of last year’s team. Before I’m going to introduce us I will first look back on the previous team and their performance in Monaco.

Last July, the team of 2022 traveled all the way to Monaco, facing an extreme challenge. They managed to become second in the Monaco Open Sea Class 2022. A huge achievement. There was strong competition in the maneuverability race, nevertheless the team managed to secure an excellent second place. This good start unfortunately could not be continued to the speed section, during the race, the boat suffered from technical defects, which prevented it from completing the race. Despite this being a huge disappointment, the team put in an excellent performance in the final section; the endurance race. With 17 laps, they sailed convincingly to first place after the competitors were far behind. Because the competitors still work with batteries, this also showed the power of hydrogen and its advantages for long distances.

With these results, the team then finished 2nd in the world championship. The entire team is extremely proud that they managed to design, build and race a hydrogen-powered boat in just one year.

To enjoy these moments one more time, the after movie is out now!

Watch the after movie here: https://www.youtube.com/watch?v=f_bzSerYCvk

Meet the team

Now a new year has arrived with a new team, a new goal and a new boat. Last August, the next generation of the TU Delft Hydro Motion Team started. We spent the last three months studying last year’s boat and designing the 2023 boat with the accumulated knowledge. Our aim is to demonstrate the applicability of new technologies by taking the next step in bridging the gap between the ‘technology of the future’ and the current norm. Within one year, we are creating an innovative boat powered by green energy to demonstrate the potential of sustainable solutions in the maritime industry.

Our goal this year is to win the Monaco Open Sea Class 2023 and become world champions with a foiling hydrogen-powered boat.

To get acquainted with the new team, the team reveal video is out now, which can be viewed here:

https://www.youtube.com/watch?v=Dty9lFvbfeY

Newsletter

This was the first newsletter of the year and there will be one newsletter every month. Do you want to receive this newsletter in your inbox? Send an e-mail to exposure@hydromotionteam.nl or click on the link below. Via the link, you can enter an e-mail address and then it is needed to confirm via Mailchimp’s e-mail. In addition, comments or questions can always be emailed to exposure@hydromotionteam.nl

See you next month!

We were at the Offshore Energy Exhibition and Conference!

On the 29th and 30th of November we were present at the Offshore Energy Exhibition and Conference in the RAI Amsterdam. We were excited to be present and we enjoyed walking around. We had a stand at the Hydrogen Area and we brought the 2022 hydrogen-powered boat. If you missed us at the event you can see a small interview with our Operations manager and our Chief of Hull and Body here: https://vimeo.com/776222559

We had a lovely time at the Offshore Energy Exhibition and Conference and we already look forward to Offshore Energy 2023! We enjoyed seeing everyone so enthusiastic to make a change in the Offshore Energy and Maritime sector. Our event director was interviewed on The Stage together with the Team managers of Forze and Green team. Our event director spoke about our goals this year and why we want to build a hydrogen-powered boat. If you’re curious you can watch it here: https://vimeo.com/776593480

The Offshore Energy Exhibition and Conference is the event where the energy transition takes place. It is Europe’s leading event for the entire offshore energy industry and an opportunity to show our solution to business leaders, highly qualified experts and professionals across global markets.

For a sustainable maritime industry we need to phase out fossil fuels and invest in greener innovations within the maritime but also the offshore industry. The developments in the maritime and offshore industry are driven by the changes in the energy sector and the necessity to work together to achieve a more sustainable future. The Offshore Energy Exhibition and Conference on the energy transition and sustainable solutions in the maritime and offshore energy industry. There is a spotlight on important drivers of change which are hydrogen, floating wind and CCS. There is attention for other offshore renewables as well like wind, wave and solar energy. The Offshore Energy events aims to show the path to a sustainable world trough renewables in the maritime and fossil energy industry. We as the TU Delft Hydro Motion Team are here to show which part hydrogen can play in a brighter tomorrow.

02-12-2022

TU Delft Hydro Motion Team at the Offshore Energy Exhibition and Conference

We are excited to be present at the Offshore Energy Exhibition and Conference on the 29th and 30th of November in the RAI Amsterdam.

The Offshore Energy Exhibition and Conference is the event where the energy transition takes place. It is Europe’s leading event for the entire offshore energy industry and an opportunity to show our solution to business leaders, highly qualified experts and professionals across global markets.

For a sustainable maritime industry we need to phase out fossil fuels and invest in greener innovations within the maritime but also the offshore industry. The developments in the maritime and offshore industry are driven by the changes in the energy sector and the necessity to work together to achieve a more sustainable future. The Offshore Energy Exhibition and Conference focuses on the energy transition and sustainable solutions in the maritime and offshore energy industry. On the event there is a spotlight on important drivers of change which are hydrogen, floating wind and CCS. There will be attention for other offshore renewables as well like wind, wave and solar energy. The Offshore Energy events aims to show the path to a sustainable world trough renewables in the maritime and fossil energy industry. We as the TU Delft Hydro Motion Team want to show which part hydrogen can play in a brighter tomorrow.

Curious about how we build a hydrogen powered boat in one year? Come visit us at stand 1.150 in the RAI Amsterdam.

Interested in seeing a finished hydrogen-powered boat with your own eyes? At the Offshore Energy we will exhibit the 2022 boat in front of the stage!

Register here: https://www.offshore-energy.biz/offshore-energy-2022/register/

28-11-2022